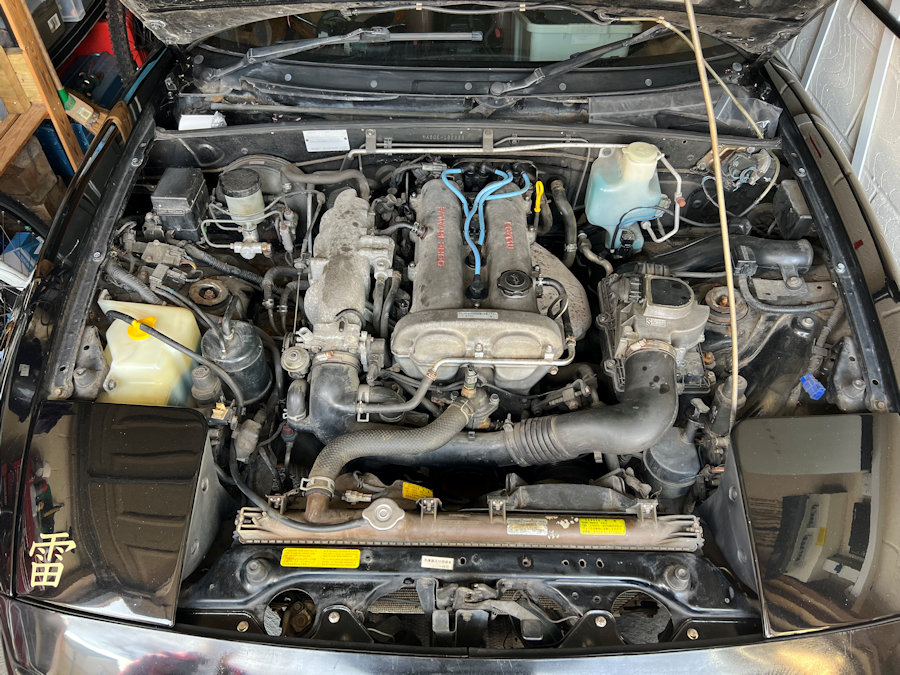

Because we plan to reuse the MX-5e engine in Yoko, we have decided to paint the camshaft cover red before we fit it with the new gasket. This will match the other bits under the bonnet of Yoko. This is a bit of a time-consuming distraction but, now is the right time to do this. It has cleaned up really well so far.

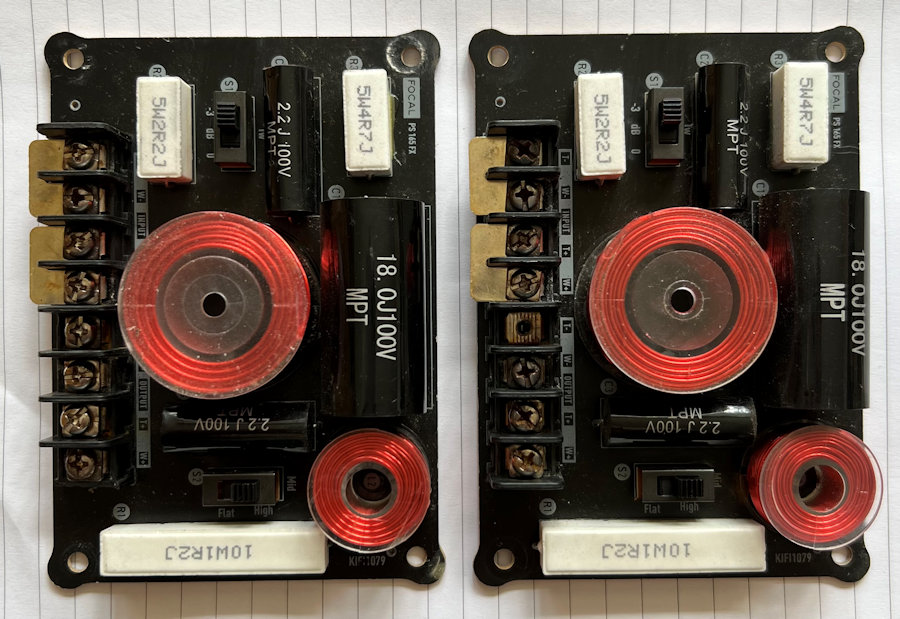

Started the morning doing small fiddly jobs! Whilst sorting our the internals of the doors, we are completely refurbishing the audio system. Whilst checking over the Focal cross-overs, we noticed the switches were jammed. Given the state of them, it is most likely rust. They have been desoldered and new ones ordered. We are also re-wiring the system with proper connectors and cables.

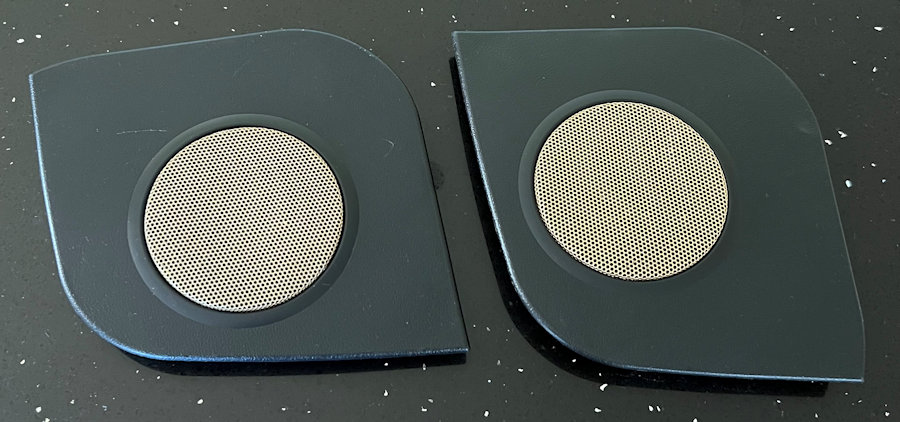

The speaker grilles have now been spray painted gold and are looking good!

We tested our 3D printed wireless phone charger before starting to take out the whole dash!

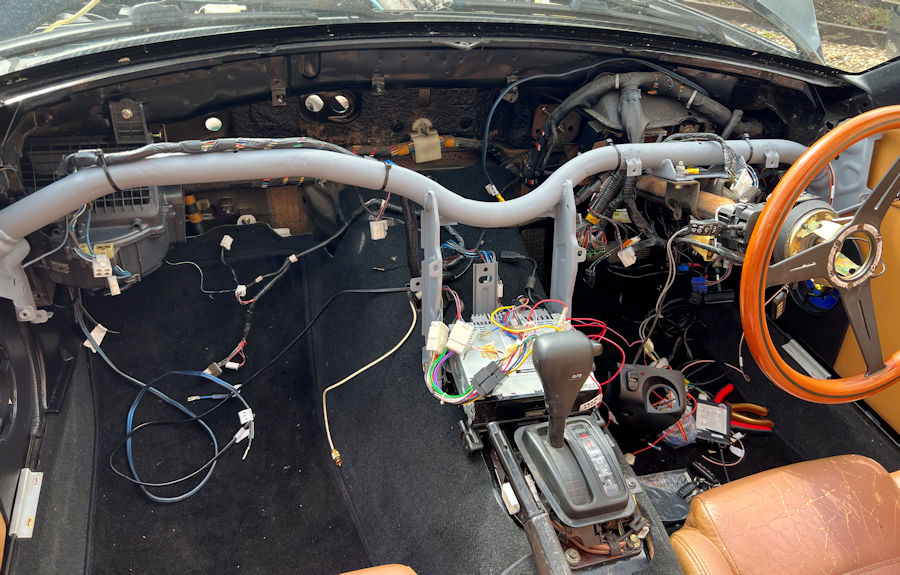

Today's big job was starting to remove the whole dash. We are currently planning to be replace it with a new black one and the whole thing has to come out to fit the new black carpet too. It is taking ages! We have never done this on an MX-5 before and it is quite the learning curve.

The big job today was to remove the dash and we got there in the end. Knowing what we know now, we could do it again much quicker! Everything behind the dash is being refurbished or removed. We are taking out the air conditioning. All the foam inside the fan unit and between the modules has crumbled to dust.

We are still contemplating not fitting a new dash and using the metal dash support to fabricate something much more radical and light-weight. The removed dash weighed in at 7.9kg. ALL of the wiring behind the dash is eventually going to be removed and replaced with a custom wiring loom that supports CAN Bus.

The speaker grilles are finally ready. The plan with the MX-5e is to paint the car metallic black and to have some subtle gold details inside and out. The brake calipers should be coming back next week having been fully refurbished and painted gold.

The cam shaft cover has been painted with etch primer, ready to take the red gloss coat. This is going to complement the other parts under the bonnet of Yoko really well, as they are the same colour.

The first job today was to drop Yoko off at Suffolk Mazda for a new clutch. We also arranged to collect a load of new parts for the MX-5e later 😎

Following Yoko reminds you what a great looking car the MX-5 NA is. If the MX-5e turns out looking this good, we will be happy.

The new switches arrived for the Focal cross-overs, so they were soldered in to place.

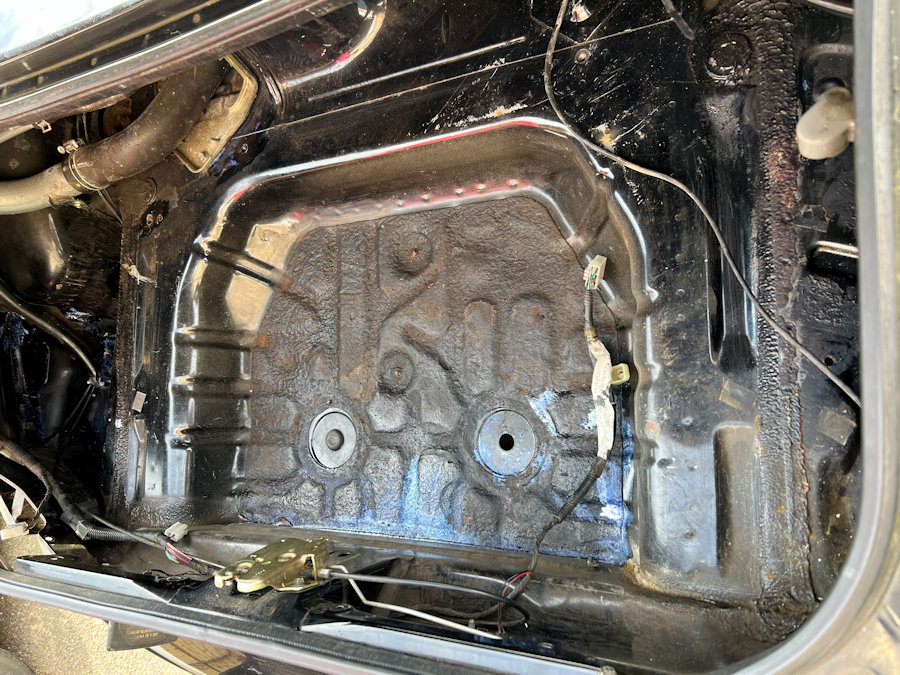

We also stripped the boot to check for rust and cleaned it up. The inside will be painted but, we found one small hole leading to the left rear wheel arch and this needs to be fixed first. Having removed the rear lights, we discovered they need new seals too.

Just to see what it looked like, we removed the metal support from the old tan dash. We are going to see if we can fabricate a much more minimalist and curvy dash around this support, to give the car a much more modern look inside. This might become a project but for now it is not a priority.

In the afternoon, we went to pick up Yoko and the rest of the black interior, including a new dash, door cards, speaker grilles, glove box and the other interior panels. We also got a delete pipe for the air conditioning unit inside the car, which should save a fair bit of weight.

The new 10" screens for the MX-5e and OSSEV® arrived in the post today. These are the basis of the entertainment and navigation system, which will be smartphone based.

The quality is really good and the touch screen is very responsive. The Apple CarPlay works brilliantly! There is a lot more detail on the MX-5e entertainments project page

These are all of the new, black interior panels which have been cleaned up and are ready to follow the new black carpet into the MX-5e.

We have new black door cards too.

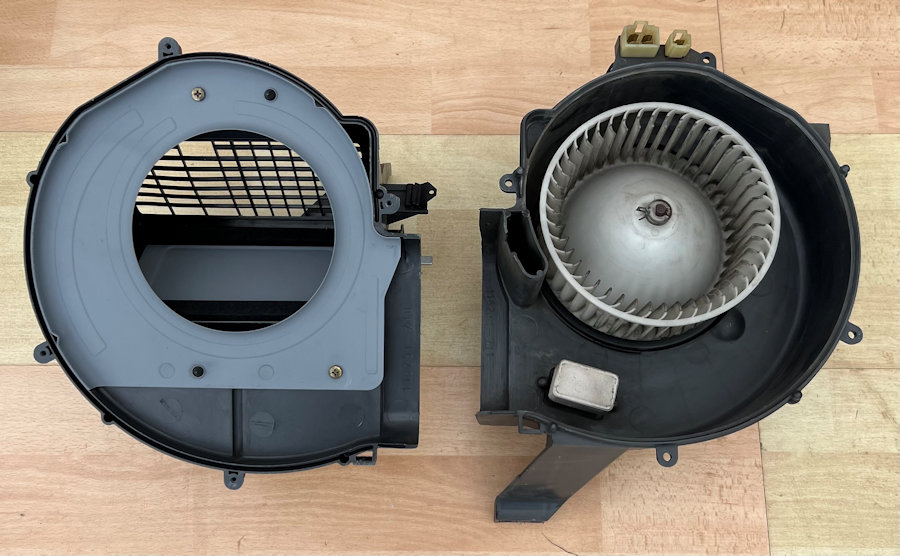

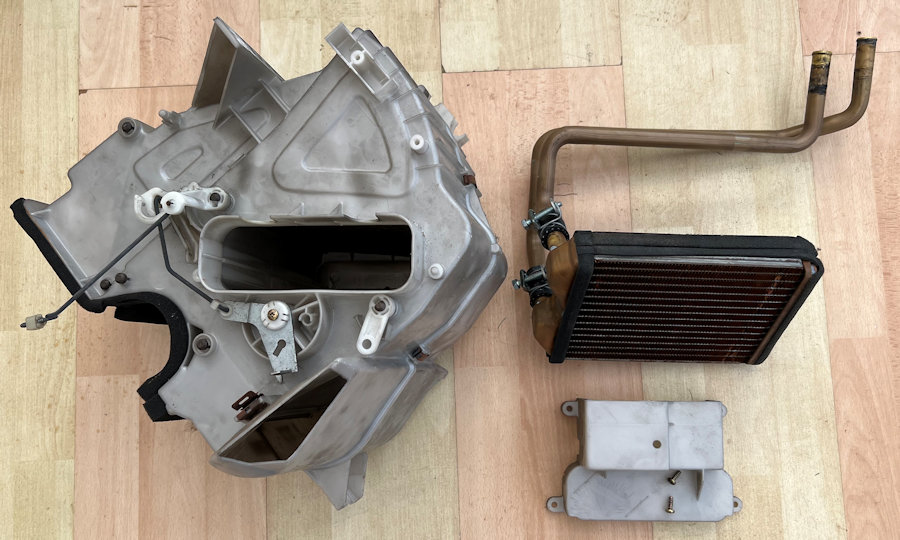

We removed the internal air conditioning unit today and have a 'delete' pipe that connects the fan unit to the heater matrix. This unit weighs 2.8kg. The rest of the air conditioning system under the bonnet will be removed later.

The air conditioning on our MX-5e had clearly not been used for many years. There was no gas in the system at all. The compressor appears to be seived as well.

We also removed the heater matrix. This unit weighs 2.9kg. The two hoses that connect this unit to the engine have been removed and a new hose is loops the inlet and outlet together.

We are seriously considering using a much lighter system for the fan and vents, which will be located under the bonnet. This solution gives us much more space inside the car. If we were to reuse this module, then the heater would be replaced with a PTC heater, powered from the main battery. I'm really not sue that we will find one small enough though. More investigation required.

With all this stuff removed, there is an amazing amount of space inside the car.

When we bought Yoko, she came with three steering wheels! One was the original Eunos wheel, which we cleaned up and is now mounted on Ethan's bedroom wall as a piece of art. Another was an old, tatty wooden rimmed Momo steering wheel with an aluminum frame. This wheel is now being used in the MX-5e and has been painted satin black. We are getting a professional to fit a stitched leather cover over the wooden rim. Rob has 3D printed as custom horn button to replace the yellow Momo one.

We have finally finished the camshaft cover. This was a bit of a distraction but we had to replace the gasket in the MX-5e as it was leaking loads of oil. We decided to tidy it up whilst it was off the car and will swap it with the one on Yoko.

We did the white lettering using a syringe and high-temperature white paint. For our first attempt, this has worked out really well.

Our plan is to experiment with the dash frame from the MX-5e and see if we can design a better dash for the car, which provides much more room. Last night we took an angle grinder to it, to remove the unwanted brackets and the whole thing has been rubbed down, rust treated and spray painted with an etch primer. It just seemed wrong to have something so rusty in the car, when we are spending so much time making everything look like new.

On the subject of making stuff like new, we started to refurbish the fan unit, in case we decide to reuse it in the MX-5e. In a 30 year-old car anything made of foam or rubber is crumbling and this fan unit is no exception. The foam seals on the internal flap were mostly gone. So we took it completely apart to refurbish it as new. Rusty parts have been rubbed down, treated and painted.

We fitted new neoprene foam strips to make the flaps air tight. The plastic only parts were pressure washed, the rest was thoroughly cleaned. Doing stuff like this is really time consuming but, we are taking the time to do it right. This car will be a keeper and good for another 30+ years of fun motoring by the time we have finished.

The first job today was to remove the sound deadening on the front bulkhead, before we fitted the new carpet. It is a thick rubber mat, with a dense layer of sound absorbent matting. We weighed what we removed and it came to 2.2kg. This was not a simple job and required the pedal box and steering column to be unbolted from the bulkhead.

We then set about installing the new carpet. This required us to remove the dash frame because the carpet runs right along the centre tunnel and up to the bulkhead. Before we fitted the new carpet, we ran some power cables for the sub-woofer, an audio cable for the sub-woofer and we replaced the dodgy wiring to the fog light.

With the carpet in place we started putting the interior trim and seats back in place. We also replaced the automatic gear selector. It is now starting to look like a car again!

This afternoon, we started putting the rear of the car back together again too. We completely stripped it, to investigate and look for any rust. We didn't really find any which is good. We are waiting for new rear light seals to be delivered before we can refit the lights.

We have black doors cards to be fitted as soon as the parts arrive to let us fix the electric windows. The only tan bits left in the car then will be these seats and we have big plans for the seats.

We removed the last badge on the car today. It's a symbolic gesture but, this car is an OSSEV MX-5e from here on.

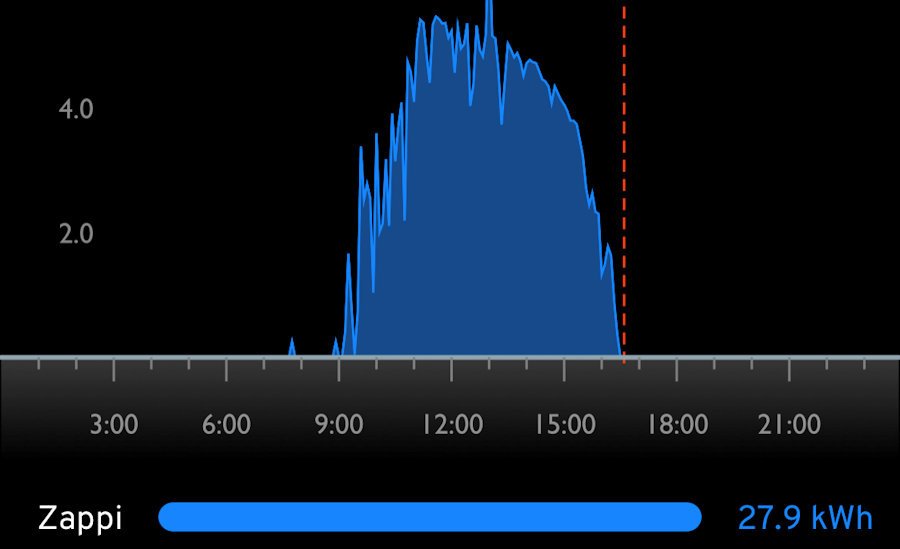

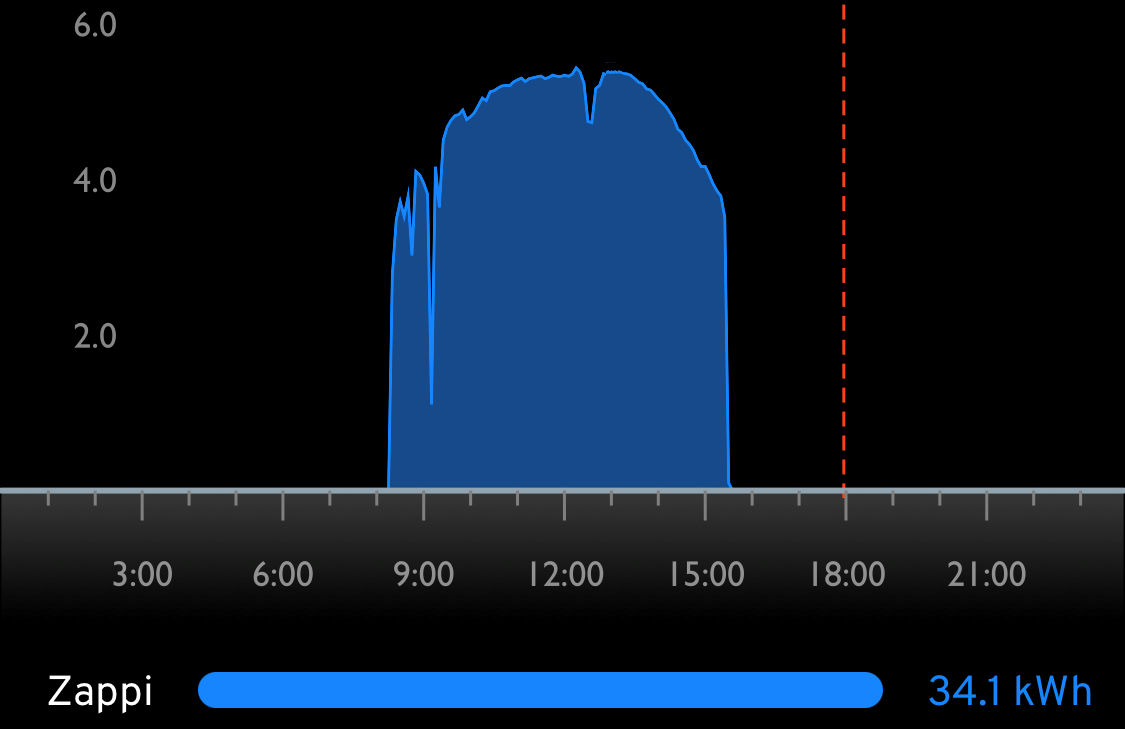

Thanks to our smart home solar project we have a Zappi smart EV charger and today it managed to put 27.9kWh into our CUPRA Born. This bodes well for our future sports EV fun! 😎

It's very wet outside and we are taking a day off. A welcome pause that gives us time to reflect on the last three weeks of busy work. The initial restoration phase of Kaminari (Japanese for lightning/thunder) nears completion and it has progressed much quicker than we had dare hoped. It helps that Ethan and Rob know the MX-5 NA / Eunos Roadster inside and out, having fully restored Yoko in the past. It is also helped by the this car having remarkably little rust considering it was made in 1992. She is already a member of the family and we can't wait to get the MOT out of the way next month and drive her on the road for the first time (under ICE power).

We got lucky and it was incredibly fortuitous that Kaminari appeared on eBay just at we kicked of the OSSEV® project. This car desperately needed the complete strip down and TLC that we are giving it. Another year left out in the rain with the faults found, would have seen this car scrapped in a few years time. It had all the required ingredients to kill an MX-5 very quickly. A leaking soft top that had been wrongly fitted, crumbling rear light seals, a disconnected drain pipe that the previous owner had left in the boot.

It was serendipity that Kaminari was an automatic as this means that no clutch pedal delete is required for our EV conversion 🙂 We had both forgotten how much fun it is to work on these cars. There is nothing (other than rust) that can't be refurbished as new or cheaply replaced. Kaminari will be transformed from an unloved daily driver and updated to be fit for the future. It will be better than new and it will be garaged from here on, fully dismantled, fully restored, fully resprayed and converted to electric power. It will provide huge fun for another 30 years or more. Let the technology injection begin! 😎

We have four goals today. The first is to paint this 'test' dash black (it is the original tan one that was in the Eunos), so we can see how stuff fits back together. This was done over the course of today.

Our second goal was to put the front bumper parts back together with the new brackets and new stainless-steel fixings. This is another time consuming job as some of the fixings are difficult to access. It is now back on the car though. The paint finish on the front bumper is not good. It has been badly resprayed by someone before we got the car. This will be fixed when the car gets a full respray in metallic black.

This morning we had another delivery from MX5 Parts. We now have the parts to fix the electric windows and then we can put the doors back together with the new door cards, handles and other parts.

The fourth job was to apply some vinyl graphics. These were done by a friend for just £2, so we will just get another set to put on the car after it has been resprayed.

The MX5 Parts delivery included new seals for the rear lights, so these have been fitted too.

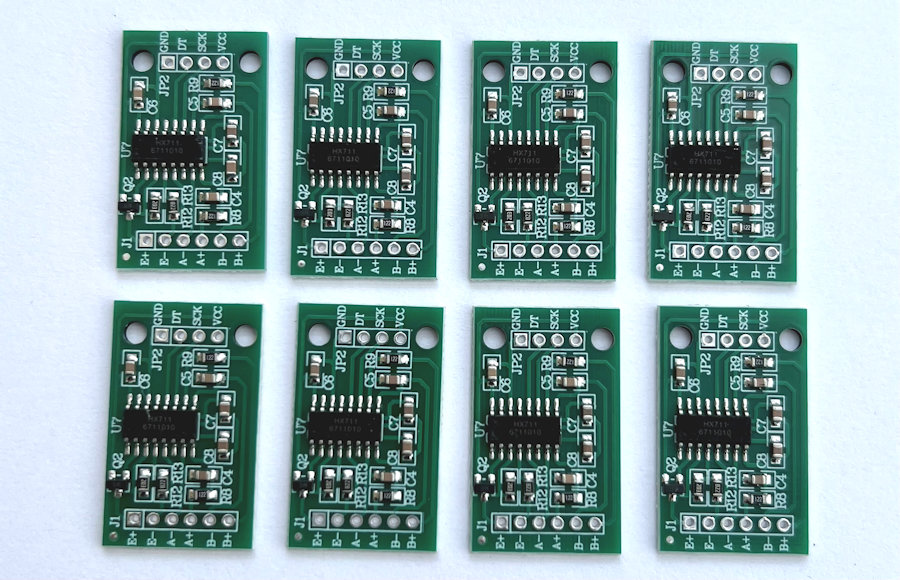

The eight load cell amplifiers arrived in the post today for our vehicle scales project. The plan is test test just one load cell initially and check we can calibrate it.

We then set about fitting the newly painted cam shaft cover to Yoko. We have used the same colour paint on the strut brace and other parts of Yoko in the past. This was a straight swap and waas done in about 20 minutes. The key things to remember are: use high-temperature silicon sealant on the gasket corners, make sure everything was clean and torque the bolts in the right order. That and putting the HT leads back correctly! We took photos before we started, just in case 😊

This freed up Yoko's cam shaft cover to be fitted to the MX-5e. We also fitted the spark plugs and torqued everything up correctly.

We are just waiting on a silicon hose to bypass the heater matrix and then we can start up the engine again. Having completely stripped the interior and dash and then put it all back together again, we are keen to check everything still works as expected 🤣

Loads of distractions today but we still got some stuff done:

On the face of it, we didn't make much progress today but we are still happy. Having stripped the interior and rebuilt large parts of the wiring loom, it was a great feeling to have the MX-5e start first time 😊

Ethan tidied up the front left corner and we will fit the new track rod end tomorrow. We now have the tool to remove the steering wheel. Rob has put in all the wiring for the entertainment system and new central 10" screen.

Over the last few days, we have been cleaning up the front hubs and brake disc dust covers and painting them. We are going to clean and underseal the inside of all the wheel arches later but, it makes sense to do this job now because we also have to fit the new track rod ends to pass the MOT.

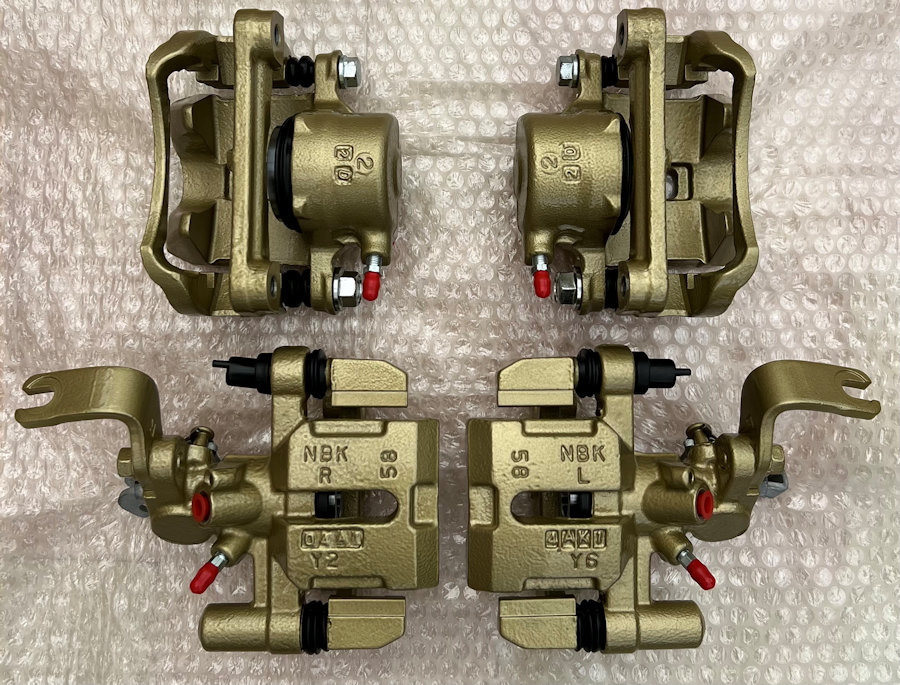

Both sides are now painted and both track rod ends fitted. We are now waiting on the refurbished brake calipers to come back from Bigg Red and then they will be fitted with new discs, pads and braided hoses.

We are not upgrading the braking system with bigger discs, calipers, etc. The reasons are simply because this is still going to be a road car, we are making it lighter and it will also have regenerative braking. From our experience of Yoko on track, the standard brakes are good enough for this application.

Another time consuming task we completed today, was to diagnose and fix the left indicators. Whilst the flasher unit worked and flashed too quickly, none of the bulbs would light up. We checked all the bulbs by swapping them left & right. We checked all the fuses. We then applied 12V directly to the wiring harness plug and they all lit up, which you would expect as all the bulbs are in parallel. This led us to think the flasher unit was broken but we could see there was an oscillating output voltage. We then cleaned up all the bulb connections and it all started working. Very strange!

Loads of progress putting the interior of the car back together today. We are really pleased with how it is coming back together.

We have modifed the wiring loom and added cables for the 10" touch screen. Rob is now designing a mount to be 3D printed for it. Previous owners had left coils of wire under the dash for the electric windows and other things. These had been cut down to length.

Tomorrow we will sort out the electric windows and new door cards. We will then test the entertainment system. It looks like we can get some steering wheel controls for the head unit.

We are using the existing instruments behind the wheel for now and the cowl that fits it. The cowl is being updated though. The plan is to add a 7" OLED screen in place of this this fairly soon.

The plan today was to sort out the doors and electric windows. We have bought a refurb kit for the electric windows, which includes new cables and fittings. These are the speaker covers which have been painted gold.

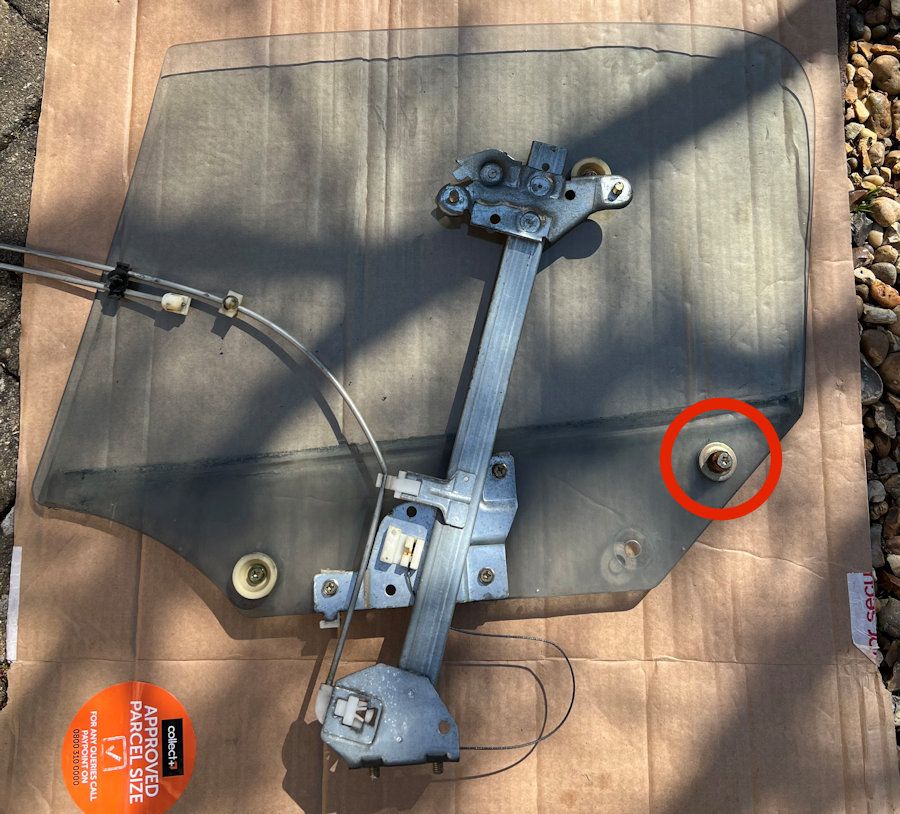

Having extracted the driver's side window and mechanism, we cleaned it up and fitted the new cables. We then realised the door glass guide bushes (circled in red) have crumbled, so we have ordered some new ones and will have to wait for them to arrive. The inside of the doors are in remarkably good condition. We have ordered new door to glass weather strips too as these warp over time and become brittle.

Rob designed and 3D printed a rough mount to check the location and mounting angle of the 10" touch screen. IT all looked good, so a proper mount can be designed now. The screen is all wired in and ready to go.

We generated 43.3kWh today, which is not the highest we have seen but getting 34.1kWh into our CUPRA Born using our Zappi smart EV charger is a new record. And this was all before 4pm, when we focus on exporting energy to get paid as much as possible on the Octopus Flux tariff.

Today was cold and windy but, we found time to address the squeaking alternator belt. Replacing this requires removal of the other belt in front of it, which is used for the power steering and air conditioning. Since both of these are going, we have no immediate plans to put it back. It also was much easier with the second radiator fan removed, which is only used when the air conditioning is on, so that isn't going back in the car either.

Not only was the alternator belt very loose, it was also crumbling into bits. It has been replaced. No more squeaking 🙂

We are waiting on parts to finish fixing the the electric windows and completing the doors, so we started a job we had planned to do after the MOT. Removing the driver's side wing was a classic example of where one rusty bolt can turn a 10 minute job into a 2 hour job 🙄 The wings are simply held on with seven 6mm bolts and one nut but, one of the lower bolts was rusted in place and rounded off. Cutting a slot in the head and using an impact driver was the only way to get it out.

Once removed, we were pleased to see just a little bit of surface rust. This is incredible really for a car of this age. All the loose rust is removed, treated and the whole wing will be undersealed.

The parts required to complete the electric windows and doors arrived this afternoon 🙂 We replace all the bolts with stainless steel equivalents unless they are load bearing.

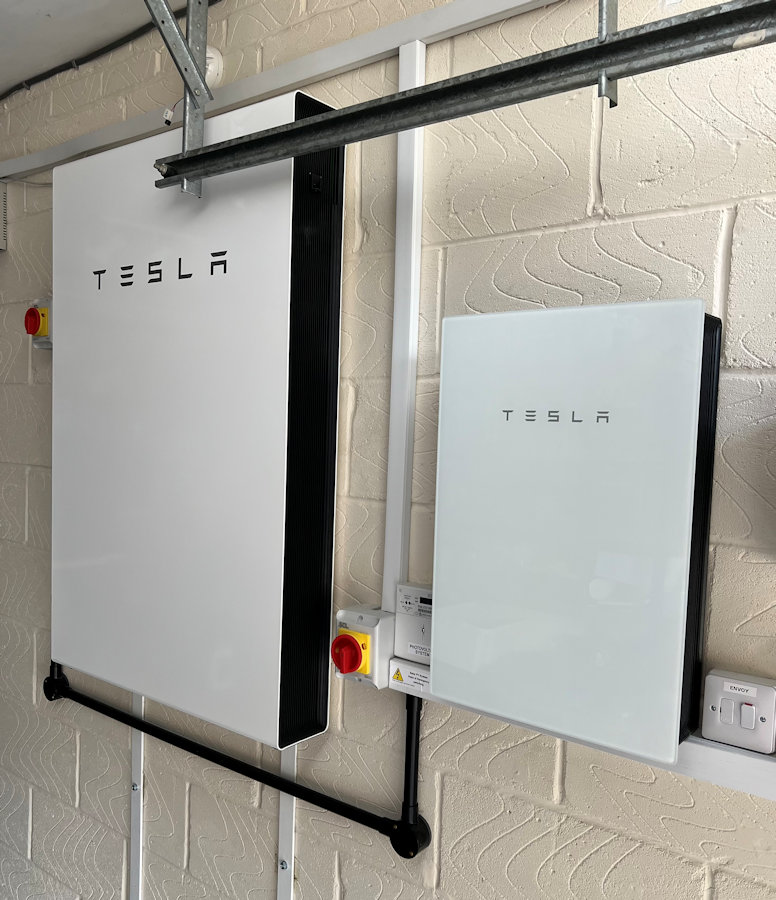

Our Tesla Powerwall is being installed in our garage next week, so the MX-5e might have to be out in the rain for a little bit. To stop it filling up with water we are fitting the hard top we bought for Yoko just in case. The hard top completely changes the look of these cars and also the driving experience.

Also tucked away in our other garage were the original wheels fitted to Yoko. These are 15" rims with 195/50R15 tyres, which is what we plan for the MX-5e, so we are going to fit them to see how they look. The tyres on these wheels are rock hard and provide little grip. The last time they were used was September 2016 on track day in Yoko and despite hammering around all day on a rough track surface, they lost virtually no tread.

Whilst rummaging through our boxes of spare MX-5 parts, we also found a hard top fitting kit and some other useful parts🙂

The larger rims look much better and the fatter tyres help too. They make the car look more aggressive and purposeful. The MX-5e sits about 2" too high though but, this will be fixed with new shocks/springs.

Just the electric windows and braking system to rebuild before can MOT the MX-5e and finally see how it drives. We already know that the suspension is quite soft.

We have decided to fit these Rota 15" x 7" rims to the MX-5e, when the time comes. They will be fitted with a CAN Bus connected Tyre Pressure Monitoring System (TPMS) and Yokohama ADVAN Neova AD08RS tyres. They will look good against the metallic black paintwork and with the gold brake calipers.

Not much progress this morning as our Tesla Powerwall was installed😎 Rob is writing a review of the Tesla Powerwall😎.

The focus of our work was on under sealing the front wheel arches.

The refurbished brake calipers arrived from Bigg Red. These have been rebuilt as new and painted gold.

The other time-consuming job we completed today was to re-cable both electric windows and replace some worn out components. Both are now working well and running smoothly.

Finished putting the doors back together with the new door cards, handles and speaker grilles. The gold gilles work well wit the gold speaker cones behind them. All the outside trims on the doors are being replaced and we have new wing mirrors on order too.